Tidal wave of megafactories drives demand for graphite development

There is unprecedented demand for raw materials to feed a tidal wave of new battery megafactories, according to international resource expert and CEO of Benchmark Minerals Intelligence Simon Moore.

Mr Moore told the US Senate, in February 2019, that the scale and speed of this growth was unprecedented and it would have a profound impact on the raw materials that fuel battery plants.

“Since my last testimony only 14 months ago we have gone from 17 lithium ion battery megafactories to 70,” Mr Moore said. “In gigawatt hour-terms, we have gone from 289 GWh to 1,549 GWh – that’s the equivalent of 22 million pure electric vehicles worth of battery capacity in the pipeline.

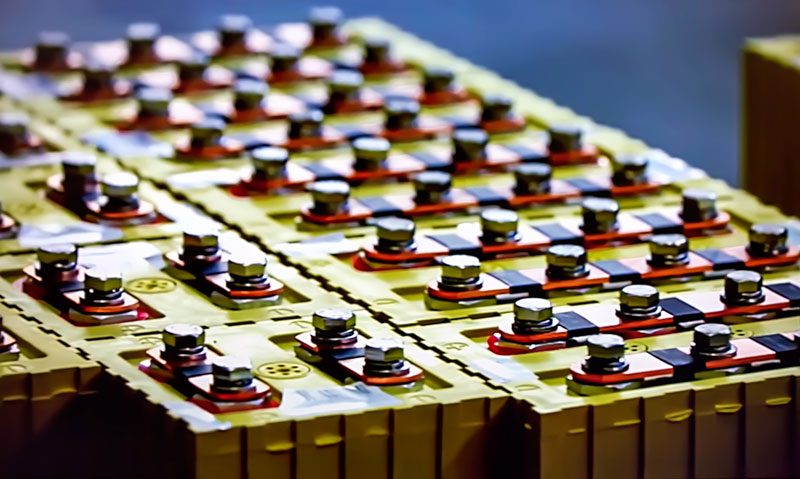

“This adds extra impetus to this mega-trend of battery megafactories and the impact on the demand for critical battery raw materials of lithium, cobalt, nickel and graphite…in the next decade the demand for lithium [used in the battery industry] is set to go up 9-times, cobalt is set to go up 6-times, nickel is set to go up 5 times, and graphite anode is set to go up 9 times.”

BatteryLimits is at the forefront of graphite project development and is working with leading graphite producers around the world. In the past five years, we have successfully completed five prefeasibility studies for graphite projects from mining through to production of graphite concentrate, and have recently been awarded a fourth full feasibility study.

In the advanced manufacturing space, BatteryLimits has completed the prefeasibility for a secondary graphite processing project in the Middle East and is now proceeding with the full feasibility. The integrated production plant is designed to produce a range of products including purified graphite, coated spheroidised graphite, expandable graphite and fine, high purity graphite film.

BatteryLimits has built a network of international partners in the graphite industry establishing itself as the premium engineering firm in this specialised arena. The is backedby the company’s extensive process engineering and project development experience across new and existing operations in the rare earths, lead/zinc and iron ore industries.